Multi Stop Route Planning Across Australian Metros

In the fast-moving world of route optimization and delivery planning, multi stop route planning across australian metros has emerged as a defining factor...

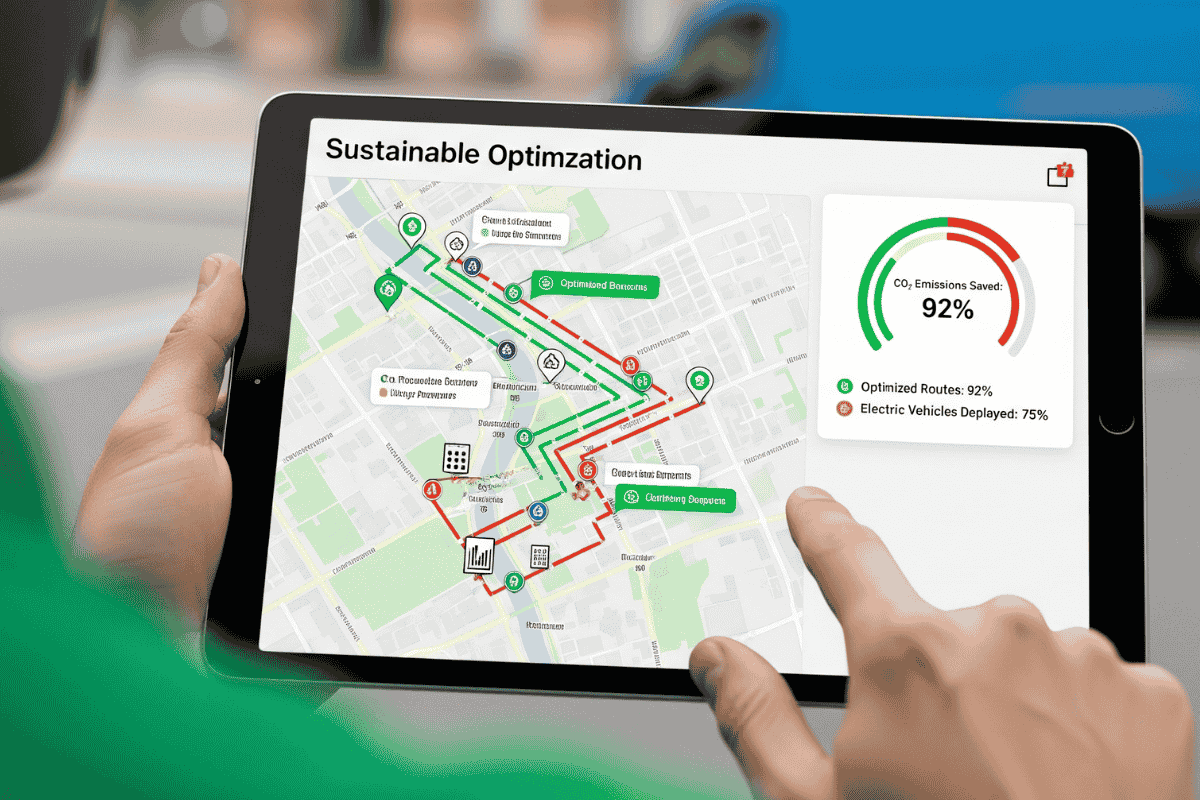

Strategies and tools for optimizing delivery routes, reducing travel time, and maximizing driver efficiency across your fleet.

97 articles

In the fast-moving world of route optimization and delivery planning, multi stop route planning across australian metros has emerged as a defining factor...

For delivery business owners grappling with inefficient routes, finding a practical, proven approach is essential. The landscape of route optimization and...

For dispatch planners grappling with inefficient routes, finding a practical, proven approach is essential. The landscape of route optimization and...

In the fast-moving world of route optimization and delivery planning, route optimization software saves hours has emerged as a defining factor for...

This comprehensive guide to ultimate guide to route planning and optimization is designed for delivery business owners who want to move beyond...

For delivery business owners grappling with poor driver utilization, finding a practical, proven approach is essential. The landscape of route...

For fleet managers grappling with high fuel costs, finding a practical, proven approach is essential. The landscape of route optimization and delivery...

For logistics coordinators grappling with late deliveries, finding a practical, proven approach is essential. The landscape of route optimization and...

In the fast-moving world of route optimization and delivery planning, dispatch and delivery planning shortcut to fast deliveries has emerged as a defining...

In the fast-moving world of route optimization and delivery planning, dispatch and delivery planning solve route changing problems has emerged as a...

For delivery business owners grappling with inefficient routes, finding a practical, proven approach is essential. The landscape of route optimization and...

For fleet managers grappling with poor driver utilization, finding a practical, proven approach is essential. The landscape of route optimization and...