The endgame of logistics is bringing a product to the customer on time. However, throughout the years this industry worldwide has seen an increase in product returns, recovery and exchanges.

A majority of people believe reverse logistics involves only handling returns, however it encompasses so much more. Nowadays this process has become a crucial part of any supply chain.

This article will not only give insight as to what is reverse logistics but also how Locate2u can bring your logistics operations to new heights!

Types of logistics

- Third party logistics (3PL)

- Fourth party logistics (4PL)

- Inbound and outbound logistics

- Reverse logistics

What to know about reverse logistics

Reverse logistics a type of supply chain management that involves moving goods from the customer back to the manufacturer or wholesaler. It can involve e-commerce and retail returns, as well as repair and recycle where goods can be resold or permanently discarded.

Reverse logistics begins at the end consumer and then moves backwards throughout the supply chain to the manufacturer or distributor. This is why some this returns process “backwards logistics”.

In some cases, customers can have additional responsibilities over the final disposal of the product. This can include recycling, resale or refurbishing.

When people used to purchase items, neither producers nor customers gave much thought to how they were disposed of, resulting in a negative impact on the environment.

However, as times have changed and people have become more aware of their impact on the environment, placing more responsibility on the customer for the final disposal of the product.

What is forward logistics?

Forward logistics is simply referred to as logistics, in which raw materials and components are moved to factories. Once these materials are finished they’ll then be transported from the factory to a warehouse or fulfillment center.

Warehousing will finish the product prior to being sold and then be delivered to the end customer or distribution center.

When Do Companies Use Reverse Logistics?

The key component of reverse logistics is to recoup value from the item or dispose of it and maintain repeat customers. Returns in e-commerce have only increased worldwide, becoming a common part of a customers purchase and a supply chain’s process.

Having a well-planned and customised reverse logistics policy can help in reducing storage and distribution costs, increase supply chain sustainability and meet customer demand.

Plenty of businesses use their return policies to set them apart from their competitors. This strategy is used to increase customer loyalty and reduce return-related losses.

Many companies use their return policies to differentiate themselves from the competition. Savvy companies use this strateg to increase repeat business and customer loyalty while reducing return-related losses.

Reverse logistics process:

Reverse logistics flow chart

Traditional Logistics vs Reverse Logistics–What’s The Difference?

Traditional logistics is the process of goods moving from the manufacturer to the customer. This involves receiving an order, packaging the item, dispatching it and delivering it.

However, there can be instances in which a customer submits a return. This is where reverse logistics takes place.

Below is a list of the reverse logistics process

- Returns

- Repairs

- Recalls

- Repackaging for restock or resale

- Recycling

- Disposal

On the other hand, direct order fulfilment, hub services, pick-and-pack services, and shipping are all components of traditional logistics. Businesses like retail and e-commerce use traditional logistics to move products to customers.

The processin which the product flows from the supplier all the way to the customer is known as product flow. This flow is usually unidirectional – the product flows in one direction from supplier to customer.

The material flow usually begins with the raw material suppliers, moves through manufacturers, warehouses, and distribution centres, and ends with the final customer.

The reverse process begins with the customer’s reason for returning and will contact the appropriate party to start the process.

The responsible party arranges for transportation of the returned product, which could involve sending a shipping label for a parcel pickup or arranging for truck pickup for larger items.

Types of reverse logistics

- Returns management

- Return policy and procedure

- Remanufacturing

- Refurbishing

- Packaging

- Unsold goods

- End-of-life (EOL)

- Delivery failure

- Leasing and rentals

- Maintenance and repairs

What Makes Up Reverse Logistics Solutions?

Effective Management

This process deals with customer product returns or prevents returns from happening in the first place. These actions should be fast, manageable, and simple because a customer will judge a company by its return flow and re-return policy. A re-return is the return of a product a second time.

Company Policy

The policies about returns that a company shares with customers are called its return policy and procedure. These guidelines must be clear and consistent. Team members should follow them as well.

Restocking

This process involves product repair, rebuilding, and reworking. Companies recover interchangeable, reusable parts or materials from other products.

Failed Delivery Procedures

With failed deliveries, drivers return products to sorting centres. From there, the sorting centres return the products to their point of origin. Some sorting centres may have staff available to identify why a delivery failed, sometimes they correct the problem and resend it.

Importance Of Reverse Logistics

Reverse logistics is crucial for supply chain managers as there is an opportunity to regain value for your operation that would’ve been lost.

Through reusing and reassigning items that might have been wasted, you can contribute more effectively to your business’ profitability by additional revenue.

An effective reverse logistics system may help your business reduce costs in a number of different ways. By having the right people and system in place, you can save on costs related to transportation, maintenance, technical support, and quality assurance.

By engaging in this activity, companies are contributing to a system geared toward a sustainable economy. Companies find new uses for disposed products through recovery, repair, and recycling. Materials that were once thought of as rubbish now have worth.

How To Guarantee Smooth Logistics

Having a clear return policy

Customers have expectations when it comes to buying and returning. They expect the same convenience in returning an item as when they purchased it.

With clear and easy-to-follow return policies, you can increase customer satisfaction. The way a company deals with returns and repairs can be a competitive differentiator.

Solid relationship with suppliers

Working closely with suppliers may guarantee that a customer gets a seamless, integrative experience rather than one that is difficult for them to navigate.

Track products both ways

Linking raw materials to the finished goods and the customer order allows you to trace materials in the event that you need to conduct a process recall.

Instead of issuing recalls for whole lines, you may discover the problem and issue them only for certain products.

Centralise your return centre and continually review logistics

Centralised return centres are warehouses and centres that process only returns. With a centralised return centre, you can effectively sort items and decide what to do with them.

Businesses are able to decide how to recover product value when there is a centre. If your business doesn’t have the funds to operate a separate returns centre, consider dedicating a portion of your warehouse or factory to returns.

Return Logistics With Locate2u

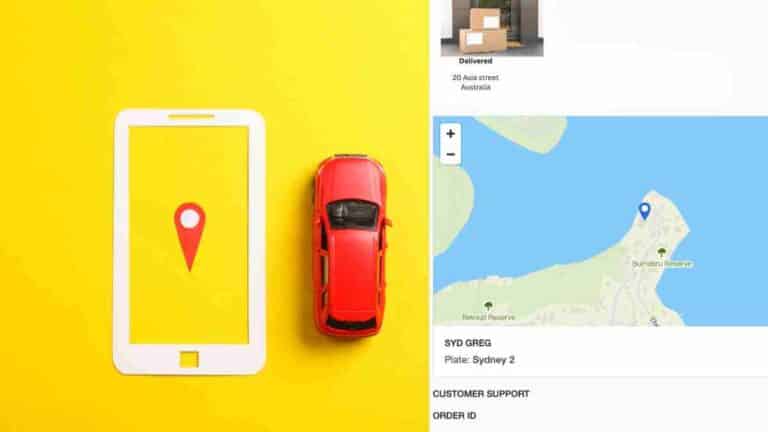

Locate2u is a delivery and field service management software that allows you to track your workers, optimise your routes, share your location and manage bookings.

Make life easier by streamlining your delivery process using Locate2u where you can save money and time. That way you can enhance your operational efficiency and give better customer service.

Learn more about why Locate2u is the logistical solution you need by clicking here!

Reverse logistics FAQs

What is reverse logistics?

Reverse logistics a type of supply chain management that involves moving goods from the customer back to the manufacturer or wholesaler. It can involve e-commerce and retail returns, as well as repair and recycle where goods can be resold or permanently discarded.

What is reverse logistics process?

- Returns

- Repairs

- Recalls

- Repackaging for restock or resale

- Recycling

- Disposal

How does reverse logistics differ for service and manufacturing industries

The difference starts after an item is repaired. In the service industry, the item can be repaired and maintain the same value as a new part. However, in manufacturing, refurbishing a new part can lead to a loss of value.

Does outsourcing reverse logistics establish a streamlined reverse logistics process?

Outsourcing reverse logistics process to a third-party logistics can establish a streamlined process that focuses on reverse logistics. However, the quality of the process is no longer under the company’s control, where customisation isn’t always an option.

What is a closed loop supply chain?

A closed loop supply chain is where businesses create new products by using production waste.

About the author

Marketing Coordinator at Locate2u having completed a Bachelor of Creative Arts, majoring in English Literature and Creative Writing. I have extensive experience in editing and proofreading, as well as creating content for a range of audiences.