It’s chaos! Running a distribution center where hundreds of deliveries need to be managed daily without a solid dispatch and delivery planning system is like navigating through a storm on the sea without a compass.

Trucks end up at the wrong location, delivery vans have to be redirected during peak traffic, delivery windows are missed, and angry customers call you. Worst of all, customers start complaining and don’t want to trust your service.

Don’t despair; dispatch and delivery planning can keep everything on track, like your compass.

In this guide, you’ll learn why you need a proper plan, what kind of software is needed to navigate through the process, and how your business can benefit from it.

Whether you are a small business or a large enterprise, you can find practical steps for optimizing dispatch and delivery planning to change your business’ delivery output.

What is dispatch and delivery planning?

Dispatch and delivery planning is the process of strategizing and coordinating the delivery of goods where and when they should be.

It’s about deciding which driver goes where and what routes to take.

Dispatch and delivery focus on:

- Route optimization

- Load planning

- Driver assignment

- Real-time adjustments

To ensure the smooth, efficient, and cost-effective movement of goods, you need dispatch and delivery planning.

Let’s explain the seven different components in detail:

Route optimization

Route optimization software is needed to make sure the most efficient delivery routes are followed. If optimized, it’s cost-effective and helps minimize delays and fuel.

More details here: What is route optimization software?

Load management

Once the routes are optimized, the next step is to manage the load.

Load management is needed to ensure the dispatch and delivery processes run smoothly. It takes into account the delivery capacity.

This helps ensure the trucks are filled to the vehicle capacity without overloading but still maximizing the space.

Scheduling and timing

Now that you have the vehicles all loaded getting the schedules ready for the day is up next.

Reducing downtime can significantly contribute to meeting expected time windows. Delivery schedules take into account traffic, road conditions, and delivery priorities, overall improving customer experience.

Real-time tracking for operational efficiency

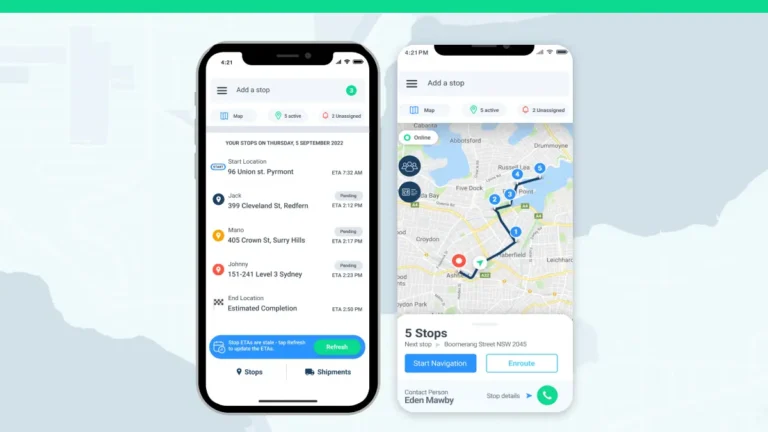

Before hitting the road, real-time tracking is needed to know where your drivers are heading.

Real-time tracking gives you visibility of your vehicles and assets. Because you know exactly where your vehicles are, a fleet manager and customers can communicate in real-time with drivers.

This is made possible with GPS tracking software to monitor the location and status of a delivery.

More details here: What is GPS tracking software?

Fleet management

So fleet managers can track drivers, and know where they are, but they need more than that.

They need to have access to real-time data to know how the vehicles are performing.

For effective delivery planning, fleet management software helps maintain vehicles to ensure the drivers are safe and vehicles are road-worthy. Collected data also helps manage fuel costs and vehicle performance.

More details here: What is fleet management software?

Delivery management

Not only do the vehicles need to be tracked, but various stakeholders involved in the last-mile delivery process need to be coordinated.

Delivery management involves assigning the delivery team to the right routes based on their experience. You’ll know exactly how drivers are driving the vehicles, ensuring they can go for training when needed.

More details here: What is delivery management software?

Customer experience

Last but not least is your customer.

According to Chain Store Age, 49% of customers who have stopped supporting a specific brand to which they’ve been loyal in the past year say it’s due to poor customer experience.

No one wants to make the customer wait. Keeping up with the delivery window is one of the top focus points when planning deliveries. That’s where route optimization software again plays a pivotal role.

The evolution of delivery systems

Now that you know how important delivery planning is, remember there are many businesses still trying to navigate through the storm with manual route planning.

Mapping out your delivery plan manually can be overwhelming (to say the least), and it’s prone to human errors.

Let’s say you own a hardware store. Manually managing dispatch for a hardware store is tough. You should figure out:

- Which driver takes which order

- How to optimize the routes

- Make sure the truck is loaded efficiently

- If a customer makes last-minute changes, you have to inform him manually

Why is it hard to manage dispatch and delivery planning manually?

A. It’s time-consuming;

B. Humans can make errors, overlooking factors like traffic and road closures;

C. There is no flexibility. If something goes wrong and a customer changes an order, there is chaos. Leading to delays having a ripple effect on the entire day.

5 Key challenges faced by businesses in dispatch and delivery

Customers want their deliveries faster. The demand for same-day delivery has increased by 50% from the COVID-19 pandemic in 2020.

For small e-commerce companies like an online home improvement tool business offering same-day delivery there are many challenges that require effective dispatch and delivery planning.

1. Route inefficiencies

Without route optimization, drivers rely on basic maps and traffic predictions that can be misleading, taking them longer to get across town.

For a driver delivering home improvement tools to the other side of the town, it can result in longer travel time, wasting fuel and time.

2. Last mile delivery troubles

Without efficient planning, there could be plenty of unforeseen obstacles waiting that can derail a speedy delivery.

Think of that driver who can’t find a parking spot near the apartment complex to urgently deliver a spare part for a customer with a burst pipe.

3. Order volume fluctuations

It’s one thing to know how many orders are made during the week, but it’s another beast to handle if there is a sale on a weekend. The business gets double the usual number of orders.

The manual dispatching systems can’t keep up, so deliveries pile up.

4. Driver management issues

Even if you have five drivers, assigning bookings manually can strain a dispatch manager. One driver can easily end up with too many deliveries, leading to inefficient resource utilization.

5. Real-time communication

There is no way to communicate directly with a driver when heading into a weather storm or an accident. Chances are the driver won’t be able to pick up a phone, and this can lead to massive delays.

The customer, on the other end – is also left in the dark about the delay.

Without real-time communication, not only are drivers left stuck in traffic, but customers are left frustrated without any updates.

Impact of poor dispatch planning on customer satisfaction

Poor planning can have a devastating impact on your business. According to a study by Dispatch Track, 61% of consumers say they are “unlikely” to purchase from the same retailer if the order arrives late.

It’s one thing to reschedule small deliveries, but big bulky deliveries can take up to weeks to be dispatched and delivered again.

According to another survey, this time by Circuit, poor deliveries can drive down sales. A staggering 72.5% of poor deliveries result in customers likely stopping recommending your service.

The stakes are high, and taking a chance on not having adequate structures and tools in place can cost you plenty of sales.

Saving costs with dispatch and delivery planning

Efficient dispatch and delivery planning is crucial for saving costs across various stages of logistics operations.

Thing of fuel costs, labor costs, and missed deliveries. It all weighs down heavily on the profit margins.

Not only does poor dispatching impact customer loyalty, but it also eats into your bottom line in unexpected ways.

Saving on fuel costs

One of the most significant areas for savings is fuel costs. It accounts for a large portion of last-mile delivery expenses. On average, the last-mile delivery accounts for roughly half of the supply chain cost.

By optimizing routes, businesses can reduce the distances traveled and the fuel consumed. According to Dispatch Track, route optimization solutions can reduce the distance driven by up to 10%.

This not only cuts fuel consumption but also reduces fleet wear and tear, saving on maintenance.

Labor costs per delivery

With better dispatch planning, drivers are more productive, making an eight-hour shift more productive.

Well-planned dispatching allows drivers to complete more deliveries or stops in a single shift. Route optimization software allows a fleet manager to assign bookings to drivers and automatically choose the most optimal routes.

This increases the number of deliveries completed per driver per day, which lowers the labor costs per delivery.

No more missed deliveries

Another key area where dispatch and delivery planning saves money is a reduction in delivery errors.

According to Parcel Lab, the average cost of a failed delivery is about $17.2. Imagine a small business delivering office supplies, toys, or accessories. The impact on an average order value of less than $200 is significant.

Manually planning delivery operations can lead to missed or incorrect deliveries. However, optimizing the delivery window and giving customers real-time tracking can increase the first-time delivery rate.

Where manual planning creates chaos, strategic dispatch planning can act as your compass, ensuring smoother operations and tangible cost savings.

NOW READ: Route Optimization: How It Works and Why It’s Essential

About the author

Mia is a multi-award-winning journalist. She has more than 14 years of experience in mainstream media. She's covered many historic moments that happened in Africa and internationally. She has a strong focus on human interest stories, to bring her readers and viewers closer to the topics at hand.