FedEx Express, a key part of FedEx Corp. and a global leader in fast transportation services, has recently unveiled a modern and expanded facility in Karlsruhe. This upgrade is designed to efficiently handle the growing volume of shipments. With this expansion, FedEx Express has also enhanced its pickup and delivery (PUD) operations in both Mannheim and Karlsruhe, improving delivery times and deadlines in these areas.

Stefan Dries, vice president of ground operations for FedEx Express Germany, says, “The facility in Karlsruhe offers our customers an even better service experience thanks to a modern infrastructure and optimized processes. We look forward to supporting our customers in expanding their business.”

FedEx Express increases capacity

The facility’s handling capacity has increased, with a warehouse of approximately 2,500 square meters – double its previous area. It includes a new truck loading ramp and 24 loading bays for efficient loading and unloading of shipments.

The warehouse’s sorting process is now largely automated, reducing sorting time by about one-third and nearly doubling its sorting capacity. An added feature is the height-adjustable and extendable conveyor belt, which simplifies the handling of packages. This expansion has also led to the creation of three new jobs, bringing the total team size at the site to 20 members.

Innovation in the logistics space

FedEx has been on an innovation mission with several initiatives putting the company at the forefront of innovation.

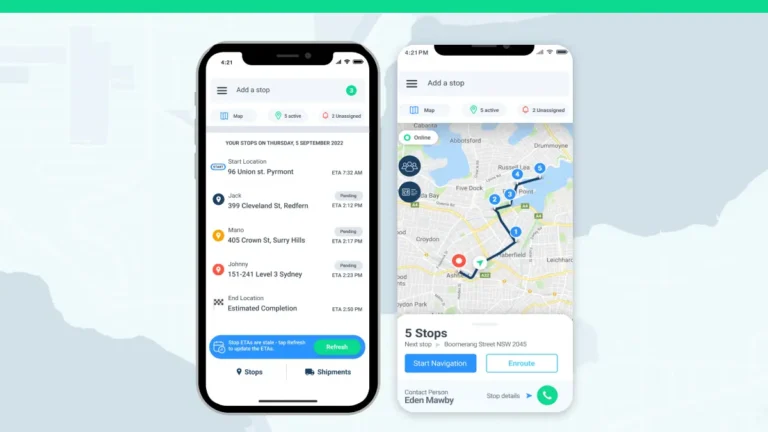

In January, the company announced the launch of FDX – a first-of-its-kind data platform. The new initiative allows customers to be part of the end-to-end journey.

German parcel delivery market

Mordor Intelligence reports the Germany Domestic Courier, Express, and Parcel Market size is estimated at US$23.95 billion in 2024 and is expected to grow at an annual compounded growth rate of 7.39% in the next five years.

However, the industry has some challenges. “Postal service providers in Germany are challenged to transport and deliver letters and parcels with fewer emissions in the future. This will require a fundamental restructuring of transport and delivery networks. Players in the market are integrating electric vehicles into their fleets to reduce the emissions from their operations,” reads the report.

Warehouse outlook

The year 2024 looks like the year of technology. Logistics companies around the world are implementing tech innovations to assist their businesses.

On the warehouse front, these facilities are experiencing some crucial benefits to automation – and staying ahead of the game and remaining competitive in the industry. Automation is assisting with aspects such as:

- Stock merging: allowing warehouse users to keep products. Often, warehouse users keep stock separately, but this practice is changing to keep stock together.

- Visibility: More order transparency is the name of the game for 2024. Providing vital information about an order, including from online platforms, will be a “must-have” this year.

- Sustainability: Warehouses are looking to operate sustainably, reducing their environmental impact. This is being done using sustainable materials and environmentally friendly energy sources.

- Restoring and customizing: There is a need for warehouses to be modern. Warehouses will also focus closely on industry-specific needs.

- Data optimization: Moving the warehouse towards operating digitally is crucial to providing speed. This year, warehouses will adapt to modern practices to carry out operations.

NOW READ: FedEx’s ‘arm of steel’ improves packing capacity

About the author

Sharl is a qualified journalist. He has over 10 years’ experience in the media industry, including positions as an editor of a magazine and Business Editor of a daily newspaper. Sharl also has experience in logistics specifically operations, where he worked with global food aid organisations distributing food into Africa. Sharl enjoys writing business stories and human interest pieces.