If you’ve ever managed deliveries with a spreadsheet, you know the struggle. I’ve been there. Transport management systems to me, is a modern genius.

Let me explain. When I worked in logistics, I juggled truckloads of cargo manually. My days were filled with endless Excel sheets, late-night recalculations, and the constant stress of ensuring every delivery made it on time.

If you’re still using spreadsheets to manage your fleet and deliveries, I get it. It feels familiar, controllable—like an old friend.

But let’s be real: it’s also chaotic, time-consuming, and prone to errors. That’s where a Transport Management System (TMS) comes in.

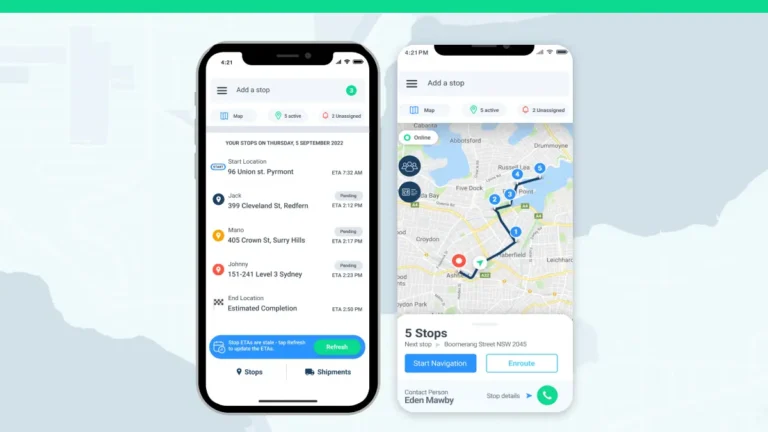

Unlike spreadsheets, a TMS doesn’t just store information; it actively optimizes deliveries, tracks shipments in real-time, and reduces your own mistakes – let’s say you miss something on the spreadsheet – disaster or worse, a missed delivery.

A TMS enhances logistics operations and ensures compliance, contributing to the overall efficiency of larger supply chain management systems.

Transport management system: What happens without it?

Before automation took over logistics, my job was all about spreadsheets. I’d plan truck routes manually, trying to match cargo loads with vehicle capacity.

Every order required multiple calculations—how much weight each truck could carry, how to optimize routes, and whether drivers could meet delivery deadlines.

One small mistake—like entering the wrong address or misjudging a load—meant delayed shipments, frustrated customers, and a long day fixing errors. You may even lose a customer as a result – not ideal in the business world.

If you’re managing logistics with spreadsheets, you’ve likely encountered:

- Human error: One typo can derail an entire delivery schedule.

- Lack of real-time updates: Once a truck leaves the warehouse, you have no way of tracking it.

- Tedious manual input: Every new order means another set of manual calculations.

- Difficult collaboration: If multiple people update a spreadsheet, version control becomes a nightmare.

A TMS helps reduce fuel and maintenance costs through optimized routes and real-time monitoring.

Despite all of this, spreadsheets have been the go-to for logistics management for years. They’re cost-effective, easy to set up, and require no special training. But are they truly efficient?

Locate2u’s software actually has a feature where you can set the capacity capabilities for each vehicle.

A transport management system is more than just a digital spreadsheet. It actively plans, executes, and optimizes deliveries, making logistics smoother and more efficient.

Unlike manual spreadsheets, a TMS automates route planning, tracks deliveries in real-time, and integrates with other business systems like ERP (Enterprise Resource Planning) and WMS (Warehouse Management System).

So, what does this mean for you? Let’s compare:

It’s time to upgrade or stay stuck

A spreadsheet might have worked 10 years ago, but logistics is moving fast. Today’s customers expect real-time updates, efficient deliveries, and seamless service. A TMS is not just an upgrade, but a necessity.

Gartner research publications provide authoritative insights within the transportation management systems sector but advise technology users to conduct comprehensive evaluations rather than solely relying on high-rated vendors.

So, what’s your next move? Will you keep wrestling with spreadsheets, or will you embrace a system that puts you ahead?

The choice is yours—but trust me, once you switch to a TMS, you’ll wonder how you ever managed without it.

About the author

Sharl is a qualified journalist. He has over 10 years’ experience in the media industry, including positions as an editor of a magazine and Business Editor of a daily newspaper. Sharl also has experience in logistics specifically operations, where he worked with global food aid organisations distributing food into Africa. Sharl enjoys writing business stories and human interest pieces.