The integration of robotics has become a cornerstone of modern manufacturing and production processes. Among the most significant advancements in this field are collaborative robots, or cobots.

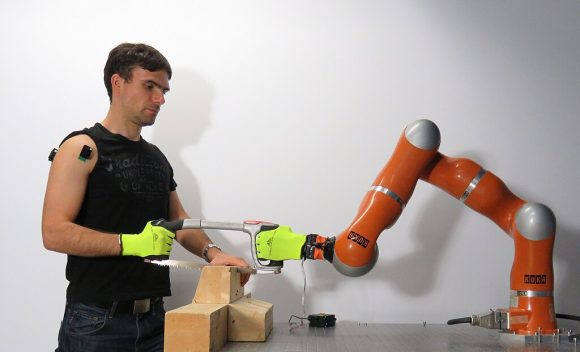

Cobots are changing the way humans and machines work together. Unlike traditional robots confined to safety cages and performing isolated tasks, cobots are designed to interact directly with human workers.

This offers a flexible, efficient, and safe solution for various industries. This guide explores the world of collaborative robots, their applications, and how they are shaping the future of automation.

But the world of robotics is vast and complex, so what exactly is a cobot?

What is a cobot?

A cobot is an industrial robot that can safely operate and work alongside humans or human workers in a shared workspace.

They are equipped with software-controlled sensors that enable them to detect objects, people, and potential collisions.

Unlike traditional robots that demand extensive knowledge and specialist engineers, cobots provide user-friendly, intuitive programming options.

What sets them apart?

This stark difference in programming between collaborative robots and traditional robots allows non-experts to easily learn and operate the robots. This reduces costs in the long run, while also facilitating quicker implementation of robotics.

What does a cobot do? collaborative robots frequently carry out manufacturing-related tasks, especially in warehouse operations.

This includes the assembly line, packaging automation, material handling, machine tending, and product quality control.

Benefits of collaborative robots

Cobots enhance the work environment for people and offer a range of advantages for industrial and manufacturing applications.

The most common benefits of cobots include increased productivity, improved quality control, consistent quality and reduced labor costs.

In short:

Collaborative robots can perform tasks that would be difficult or impossible for humans to do, such as working in hazardous environments.

They also assist in relieving human workers of physically demanding and repetitive tasks, which increases productivity.

Safety features of cobots

Collaborative robot systems are designed with human safety as a priority. They are essentially designed to work safely in close proximity to human operators.

Cobots are equipped with software-controlled sensors that enable them to detect objects, people, and potential collisions.

They facilitate direct physical interaction with qualified workers, ensuring safety through sensitive sensors and immediate responsiveness to physical disruptions, automatically stopping when they come in contact with a human coworker.

Additional methods to minimize dangers include camera vision, torque sensors, laser scanners, LED and audio feedback, and machine learning-enhanced pattern recognition.

Cobot: Types and applications

According to ISO 10218, the International Organization for Standardization, there are four types of industrial cobots, each utilizing a robot arm to enhance their design and functionality in various applications:

- power and force limiting,

- safety-rated monitored stop,

- hand guiding, and

- speed and separation monitoring.

Power and force limiting collaborative robots are designed to reduce the risk of injury and can automatically stop working when they come in contact with a human coworker.

Safety-rated monitored stop cobots employ sensors to detect the presence of human beings and automatically stop working when a human worker enters a predefined area.

Hand guiding cobots enable operators to physically guide them through a task.

Speed and separation monitoring cobots employ sensors to keep a safe distance from human workers and have features comparable to the safety-rated monitored cobots.

Fun fact: ISO 10218-1:2011 was published in 2011, but the standard is reviewed every 5 years.

Universal Robots

Universal Robots, a Danish cobot manufacturer, is the largest cobot manufacturer in the world, holding nearly half of the market share in this industry. The company’s goal is to make robotics more accessible and practical.

To date, Universal Robots has released two distinct series, with a total of seven different cobots.

Unlike traditional industrial robots, which can be complex and costly to deploy, these robots are easy to use, flexible, and affordable, making them a popular choice for businesses of all sizes.

Universal Robots’ cobots are designed to be user-friendly and adaptable, allowing for quick implementation without the need for extensive technical expertise.

Industrial robots versus cobots

Industrial robots and cobots have many similarities and several unique features.

One example: Cobots are designed to augment the human worker’s capabilities, not take their place. Traditional industrial robots, on the other hand, were primarily designed for high-volume, repetitive tasks in large manufacturing settings.

But industrial robots aren’t as versatile as cobots.

They are often confined to safety cages and can only work on preprogrammed tasks. Mobile cobots, on the other hand, can work safely in close proximity to human operators.

What is a safety cage?

A safety cage is a physical barrier or enclosure designed to protect human workers from potential hazards associated with operating industrial robots.

With the advent of collaborative robots (cobots), the need for safety cages has been reduced, as cobots are designed to work alongside humans safely without the need for such barriers.

What is the cobot market worth?

According to Markets and Markets, the collaborative robot market is projected to grow from US$1.9 billion in 2024 to US$11.8 billion by 2030.

The industry is also poised to grow at a Compound Annual Growth Rate (CAGR) of 35.2% within the same period.

As per the report, the Asia Pacific region will account for the highest CAGR during the forecast period.

The region is competitively focused on cost-effectiveness, which aligns with the affordability of cobots compared to traditional industrial robots.

Thus, cobots are an attractive choice for players in automation solutions.

ALSO READ: Robotic startups boosted by $4.2B in post-pandemic, AI-driven world

Industries that use cobots

Cobots are typically used in various production environments across industries such as the automotive industry, aerospace, healthcare, and manufacturing.

They are also used in the food industry, plastics industry, packaging industry, electronics manufacturing industry, and pharmaceutical industry.

In short:

Cobots can be used in any industry where there is a production environment with a need for repetitive tasks, material handling, or machine tending.

The projected growth of the robotics industry is promising for certain sectors, specifically electronics, automotive, and food and beverage.

These industries often require high precision, efficiency, and the ability to perform repetitive tasks, which robots are well-suited for.

Robot density

According to the International Federation of Robotics (IFR), the robot density in Asia is measured at 168 units per 10,000 employees.

This indicates a relatively high level of automation in these sectors, showing that robots are an integral part of the workforce in these industries in Asia.

The high level of robot density in Asia also underscores the region’s commitment to integrating advanced automation technologies into its manufacturing processes.

Cobot tools and accessories

Cobots are flexible and versatile, capable of being equipped with various tools and accessories for a range of tasks.

These tasks may be easy – simple pick-and-pack operations – or complex processes, like assembly and inspection.

As manufacturers develop new tools, cobots are able to learn and adapt, which in turn increases their utility across different industries.

Common examples of cobot tools and accessories:

- Grippers, which allow the robot to pick up and manipulate objects.

- End of arm tooling (EOAT), which includes various attachments for specific tasks.

- Tool changers that enable the robot to switch between different tools quickly.

- Vision systems for enhanced accuracy and precision.

- Range extenders to increase the robot’s operational reach.

- Safety features to ensure secure interaction with humans.

- Specialized software to control and program these tools efficiently.

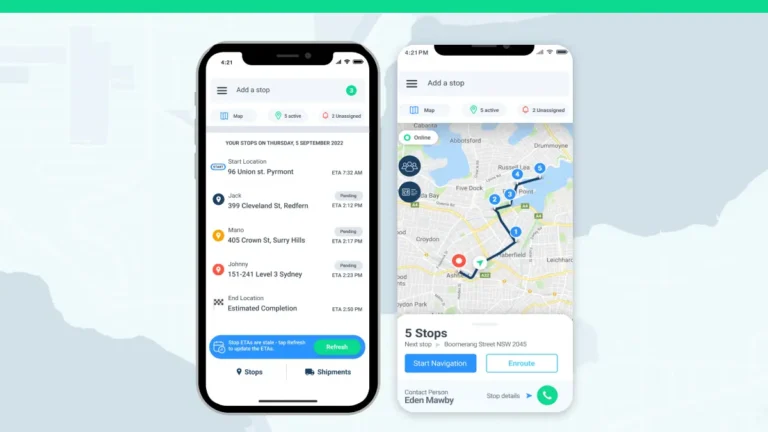

Cobot programming and integration

Cobots are significantly simpler to program than traditional robots.

They can essentially be programmed using various software options for designing a collaborative robot application, without the need for a robotic integration company or a team of engineers.

Drag-and-drop programming is the simplest method of programming a cobot.

In addition, some cobot manufacturers may also provide ways to simplify the programming process.

Costs and ROI of cobot automation

The cost of implementing cobots can vary.

Determining factors include the manufacturer, the specific features and functionalities of the robot, and the type of end-of-arm tooling required for the intended tasks.

On average, collaborative robots typically range in price from US$10,000 to US$50,000 (as of 2023).

High-end cobots

Jinan Style Machinery, for example, has an automatic smart 3D industrial laser welding cobot, selling for US$48,000.

Budget cobots

At the other end of the spectrum, a light-duty four-axis cobot could cost around $8,000. High-end collaborative robots can cost over $100,000.

When considering the cost of a cobot, it’s important to evaluate the return on investment (ROI) and the potential improvements in manufacturing quality that the cobot can deliver.

Factors to consider when buying a cobot:

- increased productivity,

- reduced labor costs,

- enhanced precision.

If it ticks all the boxes, a cobot (or a team of collaborative robots) could be a worthwhile investment for companies seeking to improve their operational efficiency.

Budgeting for a cobot

Standard Robots compiled a seven-step guide for expanding your work force to include cobots.

First, you need to identify your needs and determine the specific tasks you would like the cobot to perform. Then, shop around. Research what’s on the market, what is being developed, and compare price points and features.

You would also need to estimate operational costs. This includes ongoing expenses such as maintenance fees, software updates, and energy consumption.

You should also understand your ROI. Weight up the expenses with the potential financial benefits. Then include labor savings, productivity gains, improved quality control, and reduced downtime.

Don’t forget to keep track of additional costs. Standard Robots advises to “include expenses like end-of-arm tooling, safety components (if needed beyond built-in features), installation costs, and potential programming or training expenses for your staff.”

Finally, talk to your accountant! Since collaborative robots are more affordable than their industrial counterparts, it would be easy to make a cost-effective decision. But you will need to evaluate your needs, and talk to your accountant about your financing options.

Limitations cobots

We can’t gloss over the limitations of collaborative robots either. There are several drawbacks to consider.

These could include:

- limited payload capacity,

- limited range of motion, and

- limited precision.

However, the future of cobots looks promising, with advancements in technology and increasing demand for collaborative robots.

What to expect in the future

Manufacturers are continually enhancing cobot functionality with unique features such as integrated vision systems, making them particularly suitable for tasks requiring precision and collaboration.

According to Interact Analysis, the collaborative robot market is expected to experience exponential growth, reaching $11.8 billion by 2030, driven by evolving applications and significant market potential.

About the author

Cheryl has contributed to various international publications, with a fervor for data and technology. She explores the intersection of emerging tech trends with logistics, focusing on how digital innovations are reshaping industries on a global scale. When she's not dissecting the latest developments in AI-driven innovation and digital solutions, Cheryl can be found gaming, kickboxing, or navigating the novel niches of consumer gadgetry.