The recent logistics report by industry players shows that parcel carriers and large last-mile shippers are moving away from single-source carriers in their business relationships, seeking a more diverse carrier base.

Customers continue to want swifter and more reliable delivery times

This is the finding in a report on the state of logistics released by the Council of Supply Chain Professionals Kearney and Penske Logistics.Effective logistics management is crucial in ensuring the smooth movement of materials or goods along the supply chain.

What is last-mile delivery?

Last-mile delivery refers to the final step in the delivery process where a package is transported from a distribution center or warehouse to the customer’s doorstep.

This final step is often considered the most challenging part of the delivery process. It comes down to delivering a parcel to a customer’s doorstep fast and efficiently. By getting this last-mile right, companies ensure a positive end-to-end shopping experience.

Airfreight outlook

The report finds air freight demand is estimated to rise by 4.5% in 2024. Global logistics involves managing the flow of goods through a supply chain from its place of production to other parts of the world.

It also finds that capacity will remain sufficient. “Some major ocean carriers are adding air capacity in an effort to continue building out their end-to-end logistics networks.”

In May this year, Maersk expanded its air freight operations by launching a full-service, in-transit gateway solution in Miami. This new facility highlights Maersk’s dedication to delivering seamless and competitive connectivity to key Latin American markets.

Benefits of air freight in logistics

- Speed: Companies may need stock urgently and choose air freight as it’s a much faster option than ocean freight.

- Reliability: Airlines run strict schedules. These schedules make it a reliable option for air freight cargo. Fresh produce is often flown via airfreight so items arrive fresh at a destination.

- Efficiency: Shipping by air freight is a great time saver. A manufacturer may need an urgent part to complete a project. Placing the item as air cargo will allow the manufacturer to save time instead of waiting a few weeks for ocean freight to arrive in port.

- Logistics Management Software: Utilizing logistics management software helps businesses make routing and shipping decisions, contain costs, and track the movement of goods.

Added to the topic of air freight is the latest situation with the Red Sea. Shippers have had to look at air transport to get cargo to customers fast. This is as a result of port congestion.

Why is the Red Sea important?

The Red Sea is a crucial corridor connecting the Mediterranean Sea, the Indian Ocean, and beyond. Inbound logistics play a vital role here, involving the purchasing and arranging the inbound movement of materials, parts, or unfinished inventory from suppliers to manufacturing or assembly plants, warehouses, or retail stores.

Its strategic location gives shippers access to Europe, Asia, and Africa. The Red Sea route is the natural sailing route between these regions.

Rail sector needs to focus on technology

The report highlights Class I rail has had a challenging environment financially. This is owing to aspects like intermodal volume decreases, and increased fuel and labor costs.

“To break out of its stagnation and begin realizing sustained growth, the rail sector will need to make substantial investments in technology management, as well as significant changes in its operating models,” reads the report.

What are the benefits of rail freight?

- Lower cost: Rail transport is generally more cost-effective for moving large quantities of goods over long distances compared to road transport.

- Fuel efficiency: Trains are more fuel-efficient than trucks, which can reduce transportation costs, especially for bulk goods.

- Large volume transport: Trains can carry large volumes of freight, making them ideal for bulk commodities like coal, minerals, and agricultural products.

- Scalability: Rail networks can handle a variety of cargo sizes and types, from small containers to large, heavy items.

- Traffic reduction: Using rail for freight transport can reduce road congestion and wear and tear on highways, leading to fewer traffic jams and lower road maintenance costs.

Resilience in improving sustainability

The state of logistics report highlights that the logistics industry has shown resilience in improving sustainability. Poor logistics can lead to untimely deliveries, failure to meet customer needs, and ultimately harm the business.

It adds that there are some visible ‘pockets’ of progress with companies partnering regarding sustainable practices.

Companies are realizing the importance of operating in a sustainable way. UK parcel delivery company Evri announced a $24 million (£19 million) investment to speed up the use of electric cargo bikes for deliveries, aiming to reduce emissions.

Benefits of sustainable logistics

- Cost savings: Efficient resource utilization, energy savings, and waste reduction lead to lower operational costs.

- Competitive advantage: Companies that adopt sustainable practices can differentiate themselves from competitors. This allows them to attract environmentally conscious customers and partners.

Emerging trends in logistics

The logistics landscape is changing faster than you can say robot. Yes, automation has become a big part of logistics. Supply chain logisticians are now essential in managing the intricacy of logistics processes and the movement of resources along the supply chain.

Thanks to artificial intelligence (AI) robots can now assist warehouses with tasks like picking and sorting.

Swiss brands Verity and On have partnered to improve warehouse operations and inventory management.

These two companies aim to provide real-time inventory tracking by using fully autonomous drones in warehouses. This will reduce stockouts, misplaced items, and shrinkage, ensuring accurate and efficient order fulfillment for retail and e-commerce.

Retail companies are also seeing the value of automation. Walmart has rolled out autonomous forklifts in 19 of its distribution centers.

Here’s how the autonomous forklift operates at Walmart DC:

Trucks arrive at the DC to be unloaded. With the use of AI-powered machine vision, the forklift unloads pallets to precision and transfers these pallets to be entered into an automated storage retrieval system where goods are categorized and stored.

Benefits of warehouse automation

There are several benefits to warehouse automation. These benefits can ensure warehouses remain resilient.

- Safety and reliability: Robotics can handle heavy packaging with ease. Robotics systems can also handle toxic chemicals which allows humans to avoid toxic fumes and exposure to chemicals.

- Inventory management: Automated systems assist companies to prevent backlogs and allow the company to adapt to demand in the market.

- Strong customer satisfaction: Companies can keep customers happy by delivering goods faster.

- Resilient to changes: Automation allows the supply chain to be more agile. This includes times when demand is suddenly high or improves accuracy for prolonged periods.

What is the future of AI in warehouse management?

Mecalux is a top company in the storage systems market. It specializes in designing, manufacturing, selling, and servicing metal racking, automated warehouses, and other storage solutions. Mecalux is the leading storage company in Spain and ranks third globally, selling to over 70 countries.

The company gave insight into the future of AI in a blog post saying that eventually, repetitive and physically demanding tasks will be relegated to robots.

“Then, operators will be able to focus on work that adds greater value. AI will shorten customer service response times and improve the visibility of operations, increasing overall satisfaction.”

Maersk has highlighted some warehouse trends:

- Automation: Autonomous mobile robots will take center stage, assisting in order picking.

- Stock merging: Allowing warehouse users to keep products. Often, warehouse users keep stock separately, but this practice is changing to keep stock together.

- Visibility: More order transparency is the name of the game for 2024. Providing vital information about an order, including from online platforms, will be a “must-have” this year.

- Sustainability: Warehouses are looking to operate sustainably, reducing their environmental impact. This is being done using sustainable materials and environmentally friendly energy sources.

- Restoring and customizing: There is a need for warehouses to be modern. Warehouses will also focus closely on industry-specific needs.

- Data optimization: Moving the warehouse towards operating digitally is crucial to providing speed. This year, warehouses will adapt to modern practices to carry out operations.

Infrastructure in logistics

Good infrastructure allows logistics operations to happen fast and efficiently. Outsourcing logistics activities to external organizations, known as third-party logistics, can handle warehousing, fulfillment, and returns, further enhancing efficiency.

Imagine a container ship berthing at a port that is not properly developed. This vessel would take long to unload leading to delays and unhappy customers who are receiving the particular cargo.

Indiana Ports was recently given the go-ahead Chicago’s first sea cargo hub. This terminal will create the only all-water container route for ocean vessels to serve the greater Chicago area via the Great Lakes.

These improvements in logistics Infrastructure will allow Chicago to connect different regions, enabling businesses to reach new markets. This can expand their customer base and increase sales opportunities.

Another example is the recent introduction of intermodal service at Nevada’s inland port. It is hoped that this new service will enhance supply chain resilience.

E-commerce in logistics

The global e-commerce industry is thriving with Grand View Research predicting the industry will experience excellent growth in the next six years. Logistics managers oversee and control the complexities involved in moving goods and ensuring customer satisfaction.

“The development of social media platforms has had a major effect on online shopping,” reads the report.

Coupled with this is the fact that e-commerce businesses are using fulfillment centers to keep their logistics processes streamlined and running smoothly.

Companies like TikTok have even gone the logistics route by setting up fulfillment warehouses.

What is the bigger picture? TikTok decided to take on the complicated task of managing inventory and delivery from various independent merchants who sell goods to TikTok followers.

Another topic rearing its head in e-commerce logistics is cost of delivery. Logistics giant DHL has released an e-commerce trends report looking at online shopper trends.

The report revealed that 41% of respondents are abandoning their shopping basket because delivery is too expensive.

Delivery in online shopping

What’s the cost of expensive delivery to your business? High delivery costs may force potential customers from completing their purchases.

Outbound logistics, which involves the movement of goods from a company’s production line or warehouse to the end customer, plays a crucial role in ensuring the smooth flow of products through the supply chain.

In its report, DHL gives some valuable advice: “Have you considered offering online shoppers a discount code for free delivery? With free delivery improving shoppers’ online experience, this could persuade shoppers to make a purchase.”

One way of bringing down cost is to establish localized warehouses, which will shorten delivery times and save on transport costs.

A logistics company may even want to establish a micro-mobility hub – and bring items close to customers. Amazon has successfully launched this in Ireland.

Lowering cost of delivery for customers

You may be a store with your own delivery team. Your fleet manager may just be costing you money by using routes that are not good for business. Plus, your customers take the hit with high delivery costs.

Effective inventory control is crucial in managing and overseeing the complexities involved in the movement of goods and materials.

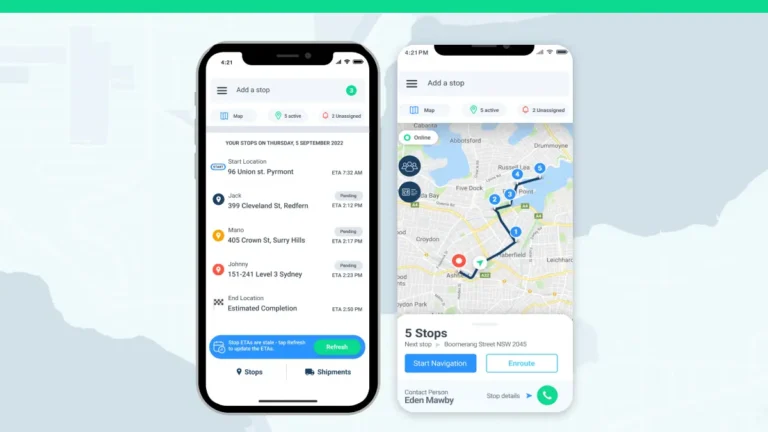

Your delivery company can use advanced route optimization software to reduce fuel consumption and delivery time. Locate2u’s software will allow your drivers to cut out traffic by choosing the shortest route, considers weather hazards, and ensures your delivery driver takes the best route.

Some stores may even give a cut-off time for deliveries. Advanced technology like Locate2u’s software will give you the freedom not to have delivery cut-offs.

Five ways to lower delivery costs

- Invest in technology – When your company implements real-time tracking systems it can improve delivery efficiency and reduce delays.

- Your warehouse can automate sorting and processing to speed up handling times.

- You can encourage the use of pick-up points or locker systems to reduce the need for home delivery.

- Your company can form partnerships with local businesses for last-mile delivery to reduce costs.

- Give incentives for customers to bundle their orders to reduce the number of deliveries.

- Implement supply chain management practices to efficiently manage the movement of goods and their components, reducing overall delivery costs.

Why is strategic location important in logistics operations?

Logistics is often about location, location, location. Logistics refers to managing the movement, storage, and transportation of resources within the overall supply chain.

Logistics facilities are mostly situated close to ports, business hubs and on specific routes to allow them to be close during the logistics process. Here are reasons why strategic location is important in logistics operations.

Reduced transportation costs

- Proximity to Customers: Being close to the customer base reduces the distance goods need to travel, lowering transportation costs and delivery times.

- Access to Major Transportation Networks: Locations near highways, ports, airports, and railways facilitate easier and more cost-effective movement of goods.

Faster delivery times

- Last-mile efficiency: Strategic locations enable quicker last-mile deliveries, meeting customer expectations for fast shipping.

- Service levels: Quick and reliable delivery enhances customer satisfaction and can be a competitive advantage.

Supply chain flexibility and resilience

- Risk mitigation: Locations that are strategically chosen can mitigate risks associated with natural disasters, political instability, or other disruptions.

- Flexibility: Being in strategic locations allows for better response to changes in demand, supply chain disruptions, or other unforeseen events.

Improved inventory management

- Centralized warehousing: Strategic locations allow for centralized warehousing that can serve multiple regions efficiently.

- Demand forecasting: Proximity to key markets helps in better understanding and forecasting demand, leading to optimized inventory levels.

Lower operational costs

- Economies of scale: Central locations can serve multiple markets, allowing companies to achieve economies of scale.

- Labor costs: Access to regions with a skilled labor force can improve operational efficiency and reduce labor costs.

Photo Credits: Canva

About the author

Sharl is a qualified journalist. He has over 10 years’ experience in the media industry, including positions as an editor of a magazine and Business Editor of a daily newspaper. Sharl also has experience in logistics specifically operations, where he worked with global food aid organisations distributing food into Africa. Sharl enjoys writing business stories and human interest pieces.